When things go wrong 4,000 feet into the mountain and two miles away from the nearest county road, or virtually anywhere on mine property, there is no 911 to call. Of the innumerable dangers facing coal miners every day, perhaps none is as omnipresent or potentially damaging as the outbreak of a fire.

Operators and industry vendors create solutions to omnipresent dangers

Underground or on the surface, the industry has learned the hard way to be ever vigilant. Between 1991 and 2000, there were 137 mine fires reported to MSHA, 76 of these were in underground coal mines. New technologies, innovations, applications and products continue to be introduced to snuff out fires the moment a spark is detected or to ensure the right tools are available to prevent further damage.

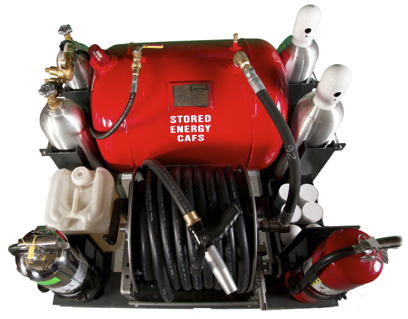

Historically most fires have been treated with water. But with the march of progress, newer dry and wet chemical agents have replaced most water-based products. Today a variety of foams, nitrogen and compressed air foam systems (CAFS) are in use or standing by throughout most mines. Chemical foams have the advantage of low surface tensions, absorb heat quickly, penetrate most fire fuels and create a vapor securing barrier. CAFS go one step further by having a nearly uniform very low surface tension (created by injected air), and have stronger bubble structures and projection capabilities than just pure foam. Nitrogen-enriched CAFS remove and displace oxygen and thus render the fuel source inert. According to the 1998 Fireline Handbook, most wet chemical foams are 40% better and more efficient at producing knockdown or flame reduction than water. CAFS are 79% better than water and 64% more efficient than just foam.