Burner Fire Control® builds custom Large Capacity Foam Systems for Helideck Fire Protection

This Super 1720 Pre-Mixed Skid mounted Pre-Mixed Foam System was manufactured in Burner’s Lafayette, Louisiana factory and will be delivered to an international client complete with the following:

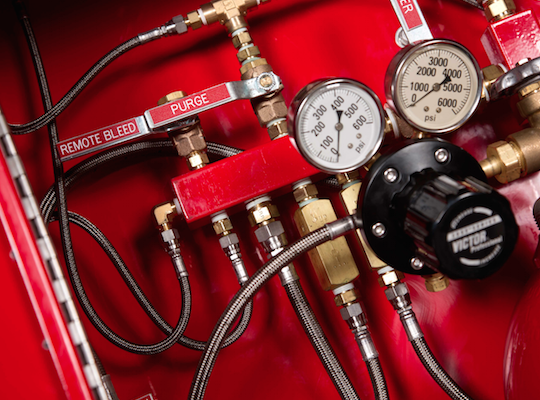

60”OD ASME Code Pressure Vessel Capacity 1720 Gallons Horizontal, 24” Inspection Opening, Internally Coated with Baked on Epoxy, 4” Fill Cap, 1.5” Tank Drain, Level Indicator, 1- 3” 150 Discharge Outlet, 250 PSI Pressure relief, 2” Stainless Steel Nitrogen Manifold, 12- 300 c/f Nitrogen cylinders with Regulators Gauges and Hoses, 24 Volt Activation with Manual override Explosion Proof, Mounted on Welded steel Skid with 4- Pad Eyes, 3- Coat Corrosion Resistant Paint system.

System General Specifications

Foam Pressure Vessel Capacity:…… 1720 Gallons

Pressure Vessel Type:……………………….. Horizontal

Pressure Vessel Diameter:…………………… 60”

Inspection Opening:…………………………… 24” With Davit

Pressure Vessel Construction Code:……… ASME Sec VIII Div 1- Stamped

Design Pressure MAWP:…………………….. 250 PSI

Design Temp:………………………………….. 450 Degrees / -20 Degrees

Working Pressure:……………………………. 200 PSI

Hydro Test Pressure:………………………… 325 PSI

Corrosion Allowance:………………………… 1/8”

Joint Efficiency:……………………………….. 100%

Internal Coating:………………………………. Yes

Fill Cap:…………………………………………. 4”

Tank Drain:……………………………………… 1.5”

Level Indicator:………………………………… Yes

Discharge Pick up Tube:…………………….. 3” 150

1” Tank Pressure Relief Valve:……………… 250 PSI

3- Coat Corrosion Resistant Paint system:. Yes

ABS Approved:………………………………… Yes

Activation:………………………………………. 24 Volt with Manual Override

Nitrogen Cylinder Expellant Gas:……………. 300 C/F 2400 PSI

Nitrogen Cylinder Quantity:…………………. 12

Nitrogen Regulator Quantity:……………….. 12

Nitrogen Manifold:…………………………….. Stainless Steel 2”

Application Design:…………………………… Per CAP-437

Skid Construction:……………………………. Welded Steel 8” X #24 I-Beam

Pad Eyes:……………………………………….. 4

Estimated Empty Weight:……………………. 7000 LB

Estimated Full Weight:……………………….. 21500 LBS